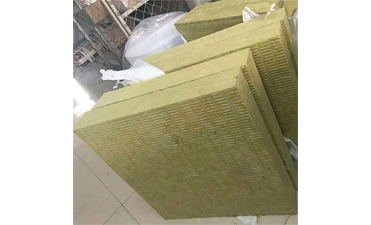

Rock wool board supplier to share with you: Rock wool boards are mostly used in construction, which is a type of exterior wall insulation. When the market share of 90% of organic insulation materials is at a standstill, as Rock wool, an inorganic material for exterior thermal insulation that has reached the fire protection level A, has ushered in an unprecedented market opportunity. Many rock wool board manufacturers have therefore expanded their processing workshops and waged price wars at the same time, giving rock wool board prices a certain advantage and attracting more customers. Construction points and precautions when using:

Construction points

1. Before construction, a special construction plan for energy-saving and thermal insulation of a project should be prepared according to the design and the requirements of this code and related technical standards, and technical personnel should be provided with technical knowledge and professional technical training.

2. The construction of rock wool board external thermal insulation system for energy-saving thermal insulation projects shall be carried out in accordance with the design documents of construction drawings that have passed the review and the special construction plan for energy-saving thermal insulation of engineering projects that have been approved.

3. The production enterprise of rock wool board external insulation system shall have professionals to provide on-site guidance during the construction process, and cooperate with the construction unit and site supervision to do a good job of construction quality control.

4. Materials entering the site must be accepted in accordance with the specifications, quantity and quality requirements before they can be stored in the warehouse, and should be kept by a special person. Curtain wall rock wool boards should be stacked overhead and protected from moisture.

5. The construction shall meet the following conditions:

5.1. The treatment of the basement wall and its cement mortar leveling layer and the installation of the embedded parts are completed.

5.2. Necessary construction equipment and labor protection supplies should be prepared.

5.3. Special scaffolding for construction should be erected firmly and pass the safety inspection. The distance between the scaffolding poles and horizontal poles and the wall surface shall meet the construction requirements.

5.4. The base wall should be solid and flat, with a dry surface without cracking, hollowing, loosening, or pan-alkali, and the bonding strength, flatness, and verticality of the cement mortar screed should conform to the (Code for Quality Acceptance of Building Decoration Engineering) GB50210 Quality requirements for ordinary plastering projects.

6. During the thermal insulation construction of the outer wall of the rock wool board, no construction shall be performed when the temperature of the base layer and the construction environment is lower than 5 ° C. No construction is allowed in windy weather above 5 levels and rain and snow. During and after construction, effective measures shall be taken to prevent rain erosion and scorching sun, and a protective layer shall be made in time. In case of sudden rainfall during construction, measures should be taken to prevent rain from washing the wall; winter construction should adopt anti-freezing measures in accordance with relevant standards.

Rock Wool Insulation Board

7. Before large-scale construction, according to regulations, the same materials, construction methods and processes should be used to make the model wall on the site, and engineering construction can be carried out only after confirmation by the relevant parties.

8. When using rock wool insulation board for construction, the operator should wear labor protection articles, protect occupational health, and pay attention to construction safety.

9. The materials that must be inspected for the rock wool board external thermal insulation system should be sent to a qualified testing agency for testing, and only qualified if used.

10. The sticking method of rock wool board should be stick stick method or point stick method, and the coating area should not be less than 50%. After the rock wool board is finished with the adhesive, the lower end of the insulation board should be pasted with the base layer. The rock wool board should be laid horizontally from bottom to top, and anchoring should be adopted while laying the board. The board seams should be naturally tight. It should not be larger than 2mm. If the slot width is 2mm, it should be filled with heat-insulating material.

11. All exiting pipelines and components that can reach rock wool board should be filled with the same material for waterproofing and sealing.

12. If the veneer layer is found to fall off during construction, it should be fixed in a timely manner by bonding or anchoring with anchors, and the exterior cladding layer construction should be performed in a timely manner.

Precautions

1. Pay attention to rain prevention, do not use in rainy days.

2. In order to keep cold, it is necessary to add a moisture-proof layer. In the case of a particularly low temperature, heat insulation is performed with resin-free rock wool. The moisture-proof layer must also be fireproof.

3. When the temperature exceeds a certain temperature, for example: 200 ° C, appropriate insulation must be added for thermal insulation, so that the thickness and bulk density of the rock wool board will not change.

4. Regarding large-diameter and flat-wall equipment for thermal insulation of rock wool products, when it exceeds 200 ° C, we must keep in mind the instructions of the rock wool board manufacturer: add insulation nails, and the outer protection should be close.

5. The equipment, insulation nails and pipes that need to be insulated are suitable for anti-corrosion and can be properly coated. There should also be no leaks. This can achieve better results.

6. The finished product of rock wool board is easy to be mechanically abraded under the condition of outdoor insulation. It should be covered with metal or plastic. Then pay attention to the joints, seal the joints, and add rubber seals when necessary.

5. The equipment, insulation nails and pipes that need to be insulated are suitable for anti-corrosion and can be properly coated. There should also be no leaks. This can achieve better results.

6. The finished product of rock wool board is easy to be mechanically abraded under the condition of outdoor insulation. It should be covered with metal or plastic. Then pay attention to the joints, seal the joints, and add rubber seals when necessary.

7. When the insulation object is placed at 90 degrees and has a certain height, the insulation layer of the rock wool board must have positioning pins or support rings, and the distance must not be greater than 3 meters to prevent the insulation material from sliding down when there is vibration. .

Our company provides custom insulation rock wool. If you have any requirements for our products, please feel free to contact us.

Copyright © Tianjin Haimen Building Materials Co., Ltd. All Rights Reserved

Sitemap