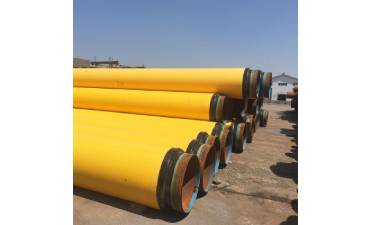

Heating pipeline manufacturer to share with you: Thermal pipes, also known as heat pipe networks, are a type of pressure pipes that transfer the heat produced by the boiler to the indoor heat through steam, hot water and other heat media Equipment to meet the needs of production and life. Starting from the boiler room, direct-fired engine room, heating center, etc., multiple heating pipes from the heat source to the building's thermal inlet form a thermal pipe network.

There are two types of medium for hot pipelines: hot water and steam. The design pressure of the heating hot water medium is 2.5 MPa or less and the design temperature is 200 ° C or less. The design pressure of the heating steam medium is 1.6 MPa or less and the design temperature is 350 or less. ℃.

Second, the characteristics of heat pipeline

The most prominent feature of hot water and steam pipelines is the thermal expansion and contraction of the pipeline due to temperature changes. At the time of installation, the temperature of the pipe is normal temperature. During the first operation (transporting heat medium), the pipe will suddenly expand due to the sudden rise in temperature. When the operation is stopped, the pipe will gradually shrink back as the temperature decreases.

Heating Pipeline

When the pipe is thermally expanded and contracted, it will cause a large push (pull) stress on its fixed points at both ends, which will cause the pipeline to deform or even damage the bracket. Therefore, measures should be taken when installing the heating pipeline (equipment) to eliminate Push-pull stress due to temperature changes.

For steam pipelines, in addition to thermal expansion and contraction, there is another feature: during the transportation of steam, condensed water will be generated due to heat dissipation and other reasons. The condensed water in the steam pipeline is extremely detrimental to the normal operation of the system. It not only deteriorates the quality of the steam, but also hinders the normal circulation of the steam, causing water hammer and noise. Therefore, measures should be taken when installing steam pipelines (set the grid to drain water and remove condensate from the installation), and the condensate generated should be discharged in time. When the pipe is thermally expanded and contracted, it will cause a large push (pull) stress on its fixed points at both ends, which will cause the pipe to deform or even damage the bracket. Therefore, measures should be taken when installing the heating pipeline (equipment is installed) to eliminate Push-pull stress due to temperature changes, and this is one of the common causes of easy damage to thermal pipelines.

The heating pipe network has played an important role in improving the living standards of the urban people, improving the urban atmospheric environment, and improving the energy utilization rate. However, the long-term use of the pipeline will cause the heating pipeline to leak. What are the reasons for this?

1. Causes of water leakage in heating pipeline

There are many factors for the formation of water leakage in heating pipelines, according to the statistical analysis of the causes of water leakage. There are the following:

01 The quality of pipes and fittings is not good

02 Leaks in pipes and connections

03 Poor anticorrosive insulation

04 Impact of other constructions

05 High water pressure and water hammer damage

06 Pipeline insulation structure falls off

07 Pipe Corrosion

Copyright © Tianjin Haimen Building Materials Co., Ltd. All Rights Reserved

Sitemap